| |

|

|

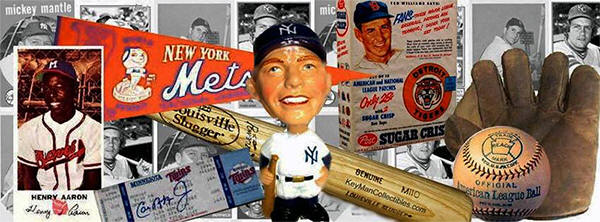

J.H. Grady MFG. Co.

Official League

Baseball |

|

|

Item Details |

-

CIRCA

- 1940

-

MANUFACTURER

- J.H. Grady co.

-

SIZE

- 9

inches - 5 ounces

-

PRICE GUIDE

- $75.00 - $150.00

Excellent-Near Mint

Condition

Due to the lack in

sales history,

value is estimated

on sales of like

baseballs.

Information

Provided by:

Keymancollectibles.com

|

|

|

|

| |

|

|

| |

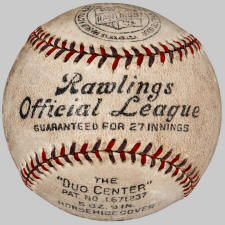

The

J.H. Grady Manufacturing Co. was

organized as a subsidiary of Rawlings

Sporting Goods in 1923 for the

production of Rawlings baseballs. John

Henry Grady, who made baseballs for

Rawlings as a youngster, was named

President. The factory opened in with

100 employees at 1310 North sixteenth

Street, and in 1931 moved to 927 Tyler

street St. Louis. MO, a little more

than 1 mile away. In 1946 Rawlings

acquired the J.H. Grady Production

Organization. This was Rawlings' entry

into baseball and softball creation.

This acquisition paved the way for

Rawlings to develop into the official

baseball of Major League baseballs in

1977.

John H. Grady assignor to J.H. Grady

held a number of patents for the

manufacturing of baseballs and

softballs. The J.H. Grady Trademark "Duro

seam" was patented in 1932, and was

used by all the Major baseball

manufactures including Spalding, Reach,

Wilson and Rawlings. They also produced the Duro-Seam Softball with the J.H. Grady

brand name. The "Duro seam" was a

patented method for sewing a hidden

seam, with a smooth surface to insure

longer wear. Another 1928 J.H. Grady

patent was used by Rawlings called "Duo

Center" The center core AKA

"Pill" used a combination of vulcanized

sponge rubber, and pure gum

rubber. The Rawlings, J.H. Grady

Patented "Duo center" is pictured

below.

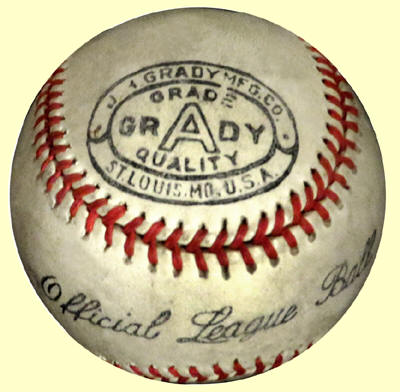

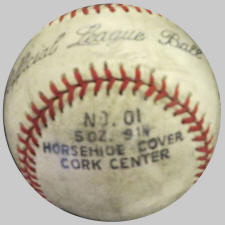

Made to the same specifications of a major League baseball the 5 inch, 9

ounce J.H. Grady No. 01, "Official

League Ball" had a horsehide cover, and

a cork center. Printed on the panel

east of the sweet spot, the baseball

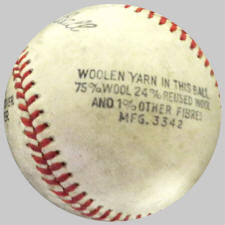

"WOOLEN YARN IN THIS BALL, 75% WOOL 24%

REUSED WOOL AND 1% OTHER FIBRES, MFG.

3342"

The manufacture of baseballs is a combination of machine and hand work.

Part of the hand work, stitching the

cover, is a relatively slow process the

fastest workers can sew only about 200

balls a week. With this limitation on

output in 1945, baseball makers were

finding it difficult to supply a

greatly increased public demand along

with continued requirements of the

armed services, although production was

said to be near the 1941 rate of

3,500,000 balls a year. About one-tenth

of the nation's baseballs were made in

St. Louis, by the J.H. Grady

Manufacturing Company, which also made

balls for other games such as

softballs, and cork balls. From about

1942 through 1945, half the total baseball

output of its factory had gone to the

armed services.

|

|

| |

|

J.H. Grady MFG. Co.

Official League Baseball |

|

|

|

J.H.

Grady Official League

Ball

Yarn specifications |

Rawlings-J.H. Grady "Duo

Center" patent No.

1.1671237 |

J.H. Grady Official

League Ball

size specifications |

|

|

|

Making Baseballs at the

J.H. Grady Factory in 1945 |

|

|

|

|

|

KEYMAN COLLECTIBLES

RELATED RESOURCES |

|

|

|